Work Package 4: Safer Batteries

(Updated: March 2020)

OBJECTIVES

Improving the safety of Li-ion batteries in electric vehicles.

PARTNERS

PARTNERS: CEA (Lead), TUM, TUV SUD, Algolion, RWTH

APPROACH

- Improve the in-depth understanding of internal short circuits and thermal runaway mechanisms and their consequences in a battery module. This will be done using post-mortem analysis of battery cells and experimental validation of electrical & thermal modelling and diagnostics at cell & module scales. Based on this deeper understanding, algorithms can be optimized to define safer operating ranges (I,V,T).

- Detect precursors to thermal runaway using novel proactive methods to enable implementation of measures starting days in advance that can prevent thermal runaway, halt its propagation or mitigate its effect thanks to the development of multi-sensing strategies and algorithms.

RESULTS SO FAR

ALGOLiON:

- Development of method to create lithium plating and to validate that it occurred via use of the early warning diagnostic algorithm. This validation was supported by conventional electrochemical methods (e.g., observing a high voltage stripping plateau on discharge subsequent to the charge cycle that produced the plating, and chemical analysis.

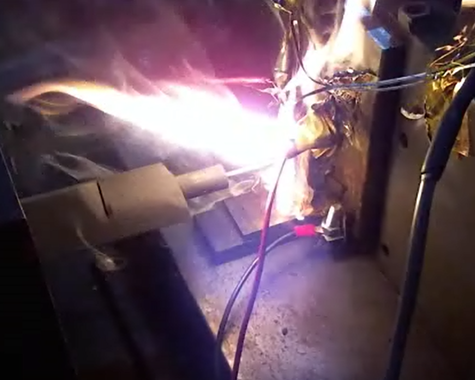

- Development of a method to reproducibly drive cells into thermal runaway using an external point contact heating technique. The point contact simulates heat generation caused by lithium dendrites that short the cell by electrically bridging between the anode and the cathode.

CEA:

- The proposed multi-sensing capability for monitoring of Li-ion cells has been validated for three basic battery abuse cases (Thermal abuse ; Short-circuit abuse ; Overcharge abuse). The measurements of the cell casing deformation (strain gages sensor) associated to electrical and thermal sensors and an associated signal processing appears to be very a promising, rapid and generate early indicator of risk of thermal runaway (almost 30 minutes in advance for some cases).

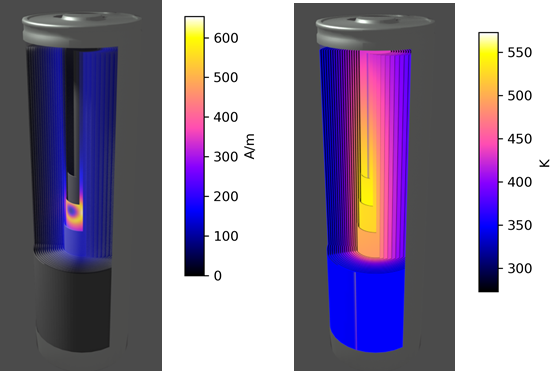

- Two multi-physic models of thermal runaway propagation have been developed at cell and module scale. Those models give the opportunity to get a better understanding of the chronology of physical events and to quantify the impact of design change on the risk of thermal runaway propagation.

- In situ XRD measurements on overcharged cells have been performed and the results are consistent with ex-situ studies.

TÜV SÜD:

- In order to perform the required cell abuse tests to provide data to the relevant EVERLASTING partners, TÜV SÜD successfully implemented an abuse method to create a soft internal short circuit within a tested cell using a crush-device and a control loop closely monitoring the cell voltage.

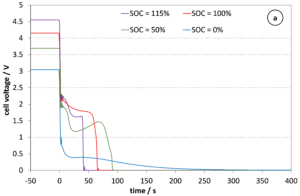

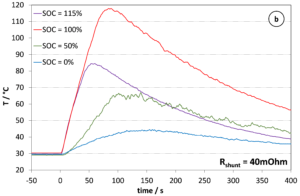

Evolution of the cell voltage, cell casing temperature and cell casing strain in direction of the cell circumference during external short-circuit discharge via 40mOhm rated resistor. The high discharge current results is rapid increase of the temperature and rapid swelling of the cell diameter. The latter indicates a rapid build-up of gas over-pressure inside the battery which activates the CID protection which shuts down the discharge process. In this way the further increase of the temperature and the thermal runaway are prevented.

| Name of the test | Number of cell

tested @ M36 |

Contributors | |

|

#0 |

“Reception Tests” and “Test during Regular operation” | All |

All |

|

#1 |

“External short-circuit” | 10

4 |

CEA

ALGOLION |

| #2 | “External low ohm (0.1 Ohm, high power) resistor in parallel with cell | 4 | ALGOLiON |

| #3 | “Defective small capacity cell in parallel with larger capacity healthy host | 6 cells |

ALGOLiON |

|

#4 |

Thermographic measurements | 1 | TUM |

| #5 | Nail penetration test (cell level) | 17 | TUV SUD and ALGOLiON cooperation |

| #6 | Crush test (cell level) | 21 | TUV SUD and ALGOLiON cooperation |

| #7 | Insertion of Ni particle into full cell for forced short circuit, also scrapping anode off of copper current collector | 12 | ALGOLiON |

| #8 | Low-T & high rates charging with over-voltage to create Li dendrites | 24 |

TUV SUD ALGOLiON |

| #9 | Discharge to low voltage to create Copper dendrites | 8 (ALGOLiON) |

ALGOLiON |

| #10 | In-situ X-Ray measurement and ex-situ analysis | 1 cell (used to manufacture different samples dedicated to X-ray measurements) | CEA |

| #11 | Overcharge | 10 (CEA)

16 (ALGOLION) |

CEA ALGOLION |

| #12 | Thermal stability in ARC | 10 | CEA |

| #13 | Differential Scanning Calorimeter (DSC) | 2 cells (used to manufacture 16 final DSC measurements) | CEA |

| #14 | Substitute one healthy cell by an early stage ISC cell in a pack of 4 cells at different configurations (4S, 4P, 2S2P) | 12 |

ALGOLiON |