Work Package 1: Improved Simulation & Modelling Tools

(Updated: March 2020)

OBJECTIVES

Development of new models and tools supporting advanced BMS research of WP2-WP7.

PARTNERS: Siemens (lead), TUM, RWTH, TUE, Voltia

APPROACH

- Research, development and delivery of virtual test benches enabling BMS coupling for testing (from MiL to HiL) and preliminary calibration in WPs 2..5

- Research of new battery model reduction techniques and the provision of reduced models to be integrated in the aforementioned simulation and validation tools and in new BMS control strategies.

WP COMPLETED

Electrochemical models have been developed by TUM and TUE. Several reduction methods have been studied and presented in different articles:

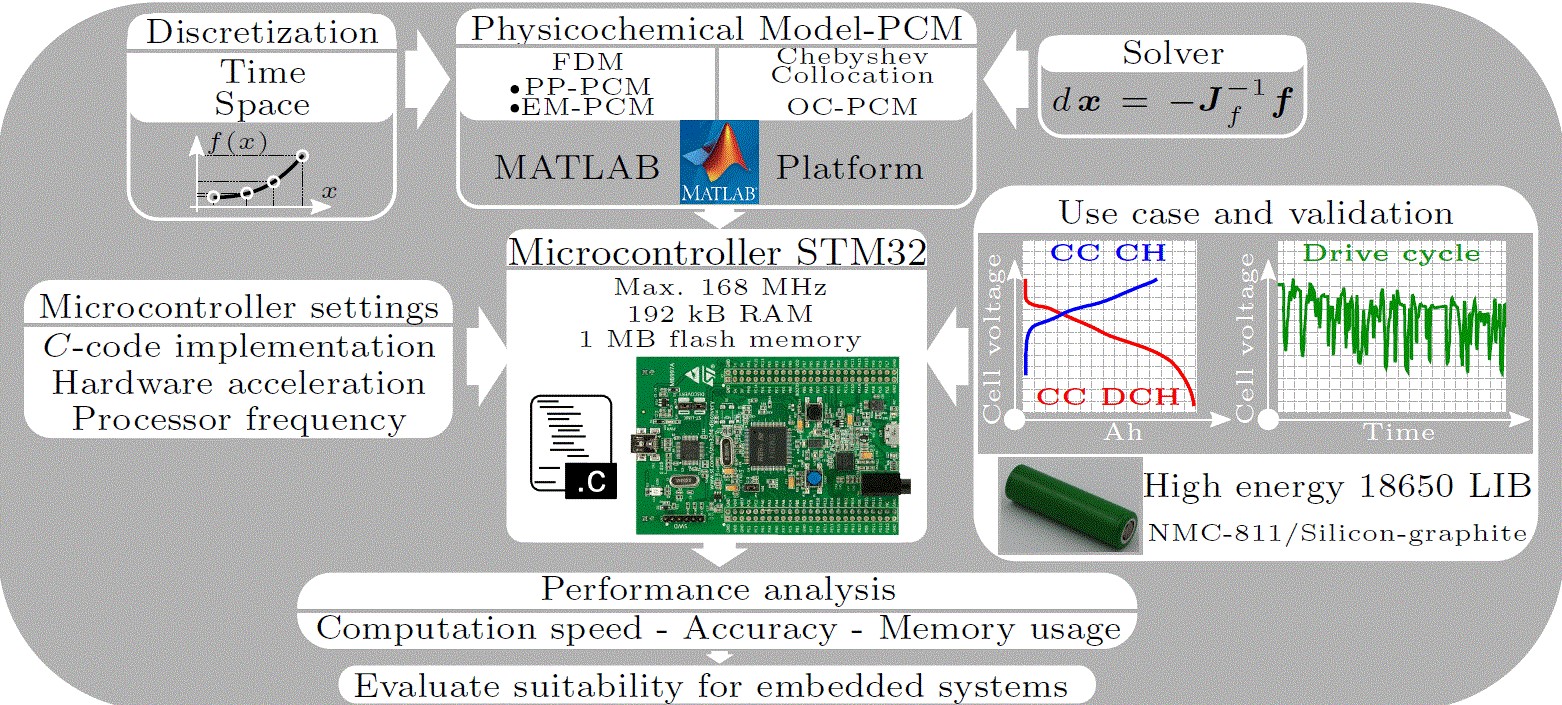

- Suitability of physicochemical models for embedded systems regarding a nickel-rich, silicon-graphite lithium-ion battery

- State estimation of lithium-ion cells using a physicochemical model based extended Kalman filter

- A computationally efficient implementation of a full and reduced-order electrochemistry-based model for Li-ion batteries

- On trade-offs between computational complexity and accuracy of electrochemistry-based battery models

- Accepted, presentation at the IEEE Conference on Decision and Control (Nice, France) in December 2019 with following open-access manuscript and data repository.

Parameterization of electrochemical-thermal models show proper simulation results with low deviations to the experimentally measured constant current charge and discharge, as well as dynamic driving-cycle battery behaviour of the INR18650-MJ1 project cell (TUM).

Successful implementation and proof of real-time calculability of three different model-order reduced, electrochemical-thermal simulation models on a microcontroller (TUM).

Protocol for a generic characterization profile of current developed by Siemens to speed up process of equivalent circuit battery model from test measurement or from electrochemical model has been used with electrochemical model from TUM & TUE. Then the equivalent circuit model has been implemented in virtual test bench.

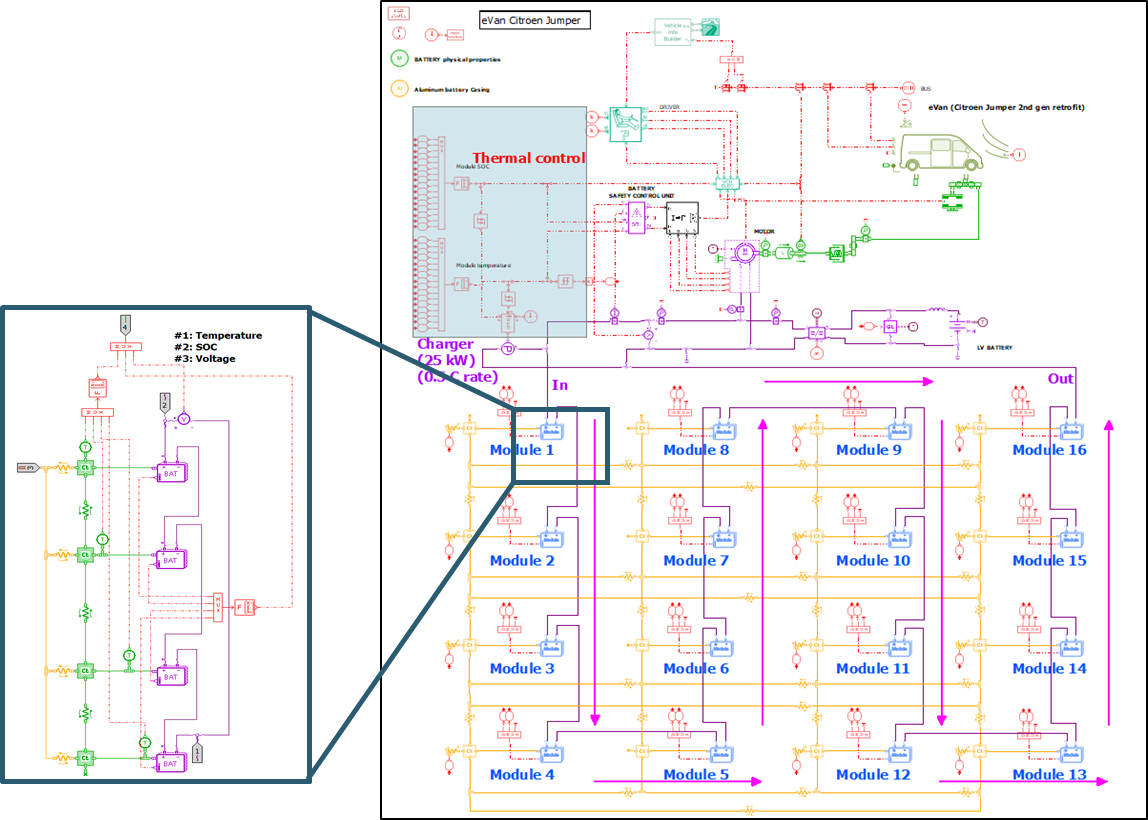

Two virtual test benches of eVan have been created by Siemens based on data from VOLTIA, powertrain measurement from TUE and equivalent battery cell model from TUM validated electrochemical model. They have been tested on different simulation environment (MiL, SiL & HiL). Demo with functional BMS connection has also been tested.

SUMMARY OF RESULTS

- Electrochemical models have been developed and validated with test measurement

- Model reduction approaches have been investigated and applied to embed electrochemical model in controller

- Workflow have been refined to allow easier battery equivalent circuit model parametrization

- Virtual tests bench models have been developed for MiL, SiL & HiL approach based on inputs from different WPs.

Real -Time implementation of MOR electrochemical-thermal simulation models on microcontroller.